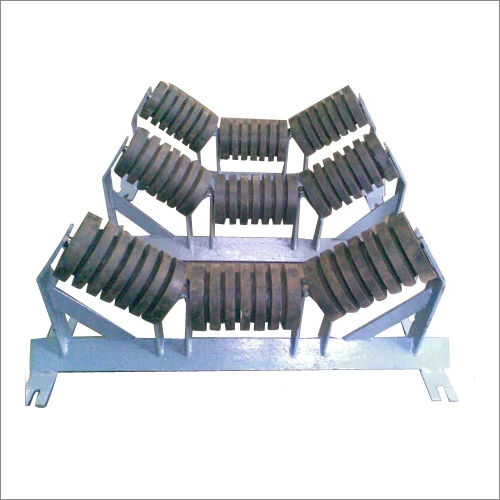

Impact Idler

Impact Idler Specification

- Type

- Screw Conveyor

- Structure

- Roller

- Belt Conveyor

- Magnetic Belt

- Roller Type

- Impact roller

- Roller Surface

- Rubber lined

- Frame Material

- Mild Steel

- Roller Diameter

- 100 mm

- Conveyor Usage

- Mining and Bulk

- Installation

- Easy Mounting

- Color

- Green/Black

- Length

- Approx. 1 meter

- Impact Absorption

- Yes

Impact Idler Trade Information

- Minimum Order Quantity

- 100 Pieces

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 10000 Pieces Per Month

- Delivery Time

- 15 Days

- Main Domestic Market

- All India

About Impact Idler

We are known for offering Impact rollers that are made up of standard steel PSV rollers with fitting rings that are intended to withstand and absorb the pressure created when items hit the belt. This roller is highly strong and gives an efficient performance that indirectly helps in increasing productivity as well as reducing labor costs. Our Impact roller which comes with rubber rings is part of the bulk handling product category that is used in belt conveyors.

Krishna Conveyor is a leading manufacturer and supplier of Impact Idlers, specially engineered to absorb heavy impact loads at conveyor loading and transfer points. Impact idlers protect the conveyor belt from damage caused by falling materials, reduce belt stress, and significantly increase the operational life of both the belt and the conveyor system.

Manufactured using heavy-duty steel frames, high-quality rollers fitted with rubber impact rings, precision-machined shafts, and premium bearings, Krishna Conveyor impact idlers ensure excellent shock absorption, smooth belt support, and reliable performance in harsh industrial environments. Our impact idlers are widely used in mining, cement, power plants, steel plants, ports, and bulk material handling industries.

Technical Specifications Impact Idler

|

Parameter |

Specification |

|---|---|

|

Product Type |

Impact Idler |

|

Idler Configuration |

3 Roll / 5 Roll |

|

Belt Width |

400 mm to 2000 mm (Customizable) |

|

Troughing Angle |

20, 30, 35, 45 |

|

Roller Diameter |

89 mm, 108 mm, 127 mm, 159 mm |

|

Roller Type |

Rubber Impact Ring Roller |

|

Frame Material |

Heavy-Duty Mild Steel |

|

Shaft Material |

EN8 / C45 Steel |

|

Bearing Type |

Deep Groove Ball Bearings |

|

Sealing System |

Labyrinth / Triple Lip Seal |

|

Surface Finish |

Painted / Powder Coated |

|

Load Capacity |

Heavy Duty |

|

Operating Temperature |

-10C to +80C |

|

Application Area |

Loading & Transfer Points |

Key Features of Impact Idler

- Absorbs heavy impact from falling materials

- Protects conveyor belt from cuts, tears, and premature wear

- Heavy-duty rubber impact rings for shock absorption

- Robust frame construction for high load handling

- Smooth rotation with low friction

- High-quality bearings ensure long service life

- Dust and moisture resistant sealing system

- Suitable for continuous and heavy-duty operations

Attributes

- Brand: Krishna Conveyor

- Product Name: Impact Idler

- Function: Impact absorption and belt protection

- Customization: Available

- Durability: High

- Maintenance Requirement: Low

- Operational Efficiency: Enhanced conveyor reliability

Applications of Impact Idler

- Mining and Mineral Handling Plants

- Cement and Clinker Plants

- Thermal Power Stations

- Steel and Metal Processing Industries

- Fertilizer and Chemical Plants

- Ports, Terminals, and Ship Loading Systems

- Bulk Material Handling Conveyors

Why Choose Krishna Conveyor?

- Trusted impact idler manufacturer in India

- Precision-engineered products with strict quality control

- Customized solutions as per conveyor design and load

- Competitive pricing with timely delivery

- Proven performance in harsh industrial conditions

- Strong after-sales and technical support

FOQ / FAQ Impact Idler

Q1. What is an impact idler?

An impact idler is installed at conveyor loading zones to absorb shock from falling materials and protect the conveyor belt from damage.

Q2. Where are impact idlers used?

Impact idlers are used at loading and transfer points where bulk material drops onto the conveyor belt.

Q3. What is the difference between an impact idler and a carrying idler?

Impact idlers are fitted with rubber impact rings to absorb shock, while carrying idlers support the belt during normal material transport.

Q4. Can Krishna Conveyor provide customized impact idlers?

Yes, we offer customized impact idlers based on belt width, troughing angle, load conditions, and application requirements.

Q5. How do impact idlers improve conveyor system life?

They reduce belt damage, minimize maintenance downtime, prevent belt sag at loading points, and enhance overall conveyor reliability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Impact Idlers And Rollers Category

Impact Roller

Minimum Order Quantity : 10

Type : Belt Conveyor

Structure : Chain

Belt Conveyor : Magnetic Belt

Industrial Impact Roller

Minimum Order Quantity : 100 Pieces

Type : Screw Conveyor

Structure : Chain

Belt Conveyor : Magnetic Belt

Industrial Impact Idler

Minimum Order Quantity : 100 Pieces

Type : Screw Conveyor

Structure : Chain

Belt Conveyor : Magnetic Belt

Impact Conveyor Roller

Minimum Order Quantity : 100 Pieces

Type : Belt Conveyor

Structure : Chain

Belt Conveyor : Magnetic Belt

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS